Wool Trip by Hannah Fettig

Every piece of knitwear is like a piece of history. With every stitch, every made piece becomes part of our own story. That yarn you bought on holiday, or that first, wonky piece you made without a pattern. These are memorable pieces. What if you could inject even more of a backstory to your knitting?

Hannah Fettig of Knitbot went on a wonderfully inspirational journey this summer, which resulted in Wool Trip – a truly limited edition, small batch yarn with a serious backstory – and now at Loop!

As you read the story below, you’ll understand how excited we were when Hannah offered to send us the small amount of yarn left after the summer, and Loop is very proud to now be the exclusive stockist of this unique piece of knitter’s joy.

Hannah is the brilliant knitwear designer and writer of several books, collaborations with Quince & Co and best selling patterns that we have come to love and rely on. Although she’s not really looking to get in to the yarn producing business, what do you do when there’s an organic wool farm not too far from where you live, who happen to have left over wool?

So starts the Wool Trip journey, in the hills of Springvale, Maine, at the Noon Family Sheep Farm.

“The Noon’s sheep have been bred to be multipurpose. The flock started in the 70’s as Columbia sheep, a United States-native breed used for both meat and wool production. From there, the Noons selectively mixed in other breeds. Karakul sheep brought brown and black colors into the flock. Polypay and Suffolk improved the meat. Leicester and Rambouillet contributed longer and finer wool. “These are not show sheep,” Jean Noon says. Maybe they aren’t thoroughbreds, but their heritage makes them work well for a variety of uses. They produce meat, cheese, yogurt, sheepskins, and (of course) wool. The wool fiber is medium in diameter, not as soft and thin as some breeds, but not tough and thick either. When spun, it lends itself to a worsted-weight yarn that’s warm, durable, and wearable. It seems only fitting that these versatile, practical animals would produce a versatile, practical yarn.”

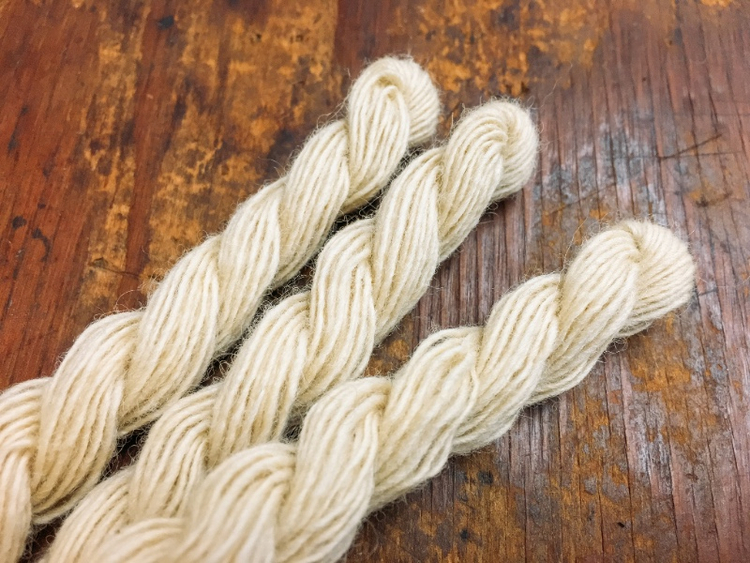

Next Hannah and her husband Abe drive their wool over the border to Vermont, and the Green Mountain Spinnery, an employee-owned cooperative, where it is scoured, combed and spun. With some machinery dating back all the way to 1896, this is a fascinating operation that preps the yarn directly from the sheep to finished yarn.

“Amazing vintage machinery being maintained and run by clever and friendly people. “The great things about these machines is that they never become obsolete.” Kate says. “As long as you maintain them, they’ll run forever.””

“Next, the wool goes into a picking machine. This takes the chunks of wool and loosens them up, then blows them through a chute into an enclosed room, where they flutter down and land all mixed up. It’s like shuffling a deck by throwing all the cards in the air.”

“Seeing the process also leaves us meditating on the fractal nature of wool garments. Individual wool fibers interlock to become roving. Roving is spun into plys. Plys are twisted into yarn. Yarn is knitted into fabric. At each step it becomes bigger, stronger, and more useful.”

A few weeks later, the wool is all spun up and ready for the third and final step – the dye!

One last, slightly longer drive to Canada where the husband-wife duo Julie Asselin and Jean-François “JF” Mallette will turn this small batch production into two different colours, one grey and one pink.

“Hand-dyeing always results in some variations in color saturation, but there are a number of factors that can be adjusted to make the colors more or less variable. Less water makes for more variation, since dye and yarn are concentrated in a smaller areas and there are more likely to be hot spots. Hotter water also makes for more variation, since the dye sets up faster before it has a chance to fully circulate. In this case, we’re aiming for fairly consistent color, so she uses more water, starts it off cool, and keeps the temperature relatively low.”

Talk about a yarn journey! Every yarn in our shop might have a similar story to tell, but rarely do we get such a well documented glimpse into a personal dream becoming reality. Wool Trip absolutely oozes with provenance and storytelling. As a conclusion, we really couldn’t put it any better than Hannah herself:

“Hold a skein under your nose and inhale, and it’s all there. The sheep at Noon Family Sheep Farm. The vegetable-based organic spinning oil that kept the wool moving through the machines at Green Mountain Spinnery. The colorful dyes in Julie and JF’s studio. We take a sniff and can’t help but smile as it all comes back to mind. We hope that smell puts smiles on the faces of knitters, too, as they imagine where their skein of yarn has been, and then start knitting their own chapter into its colorful history.”

Now you have the full backstory of the Wool Trip yarn, the rest is up to you. Where will you take the journey next? You can shop this limited edition yarn now on our website or in store. Every purchase of Wool Trip comes with a free copy of the Wool Trip Crew Neck jumper pattern. And you can read the full Wool Trip story in detail here. Many thanks to Knitbot for letting us share their images.

∞∞∞

Time to announce the winner of last week’s giveaway. The lucky winner of the much coveted Knit Kit On A String is Josiekitten – congratulations!

∞∞∞

Our Christmas opening times are here!

If you are planning a visit to Loop over the Christmas and New Year period. We have also listed last posting dates for Christmas if you are ordering from the online or London shop and want your parcel to arrive in time.

∞∞∞

We will be at the Edinburgh Yarn Fair in March and we are just over the moon about it. We hope to see you there!

∞∞∞

PS. We have been nominated for the British Craft Awards 2017! Please show us your support by clicking on the image above to vote for Loop as the Knitting and Crochet Retailer Of The Year. Voting is open until 20th December 2016. Everyone* who votes will be entered into a prize draw to win one of 5 £100 Amazon Vouchers (*Prize eligible to UK Residents only but anyone can vote!)

Leave a Reply